Engineers need to know the range of motion and force involved in mechanical designs before mechanical designs become viable pieces of equipment that provide operational and worker safety.

It is important to consider that force generally indicates push or pull motion. The push or pull motion can be magnetic, gravitational or electrical in nature. Force is measured by a meter. Note that force is measured in pounds. For instance, a lion’s bite is measured as 1235 pounds of bite force.

A force meter measures tension and compression such as the force compression of the lion’s bite. When tension and compression are measured, it acts on a sensor and is commonly referred to as a transducer.

How Force Sensors Act on Load Cells

. Pneumatic load cells

. Hydraulic load cells

. Magnetostrictive load cells

. Piezorestive load cells

. Inductive and reluctance load cells

. Strain gauge load cells

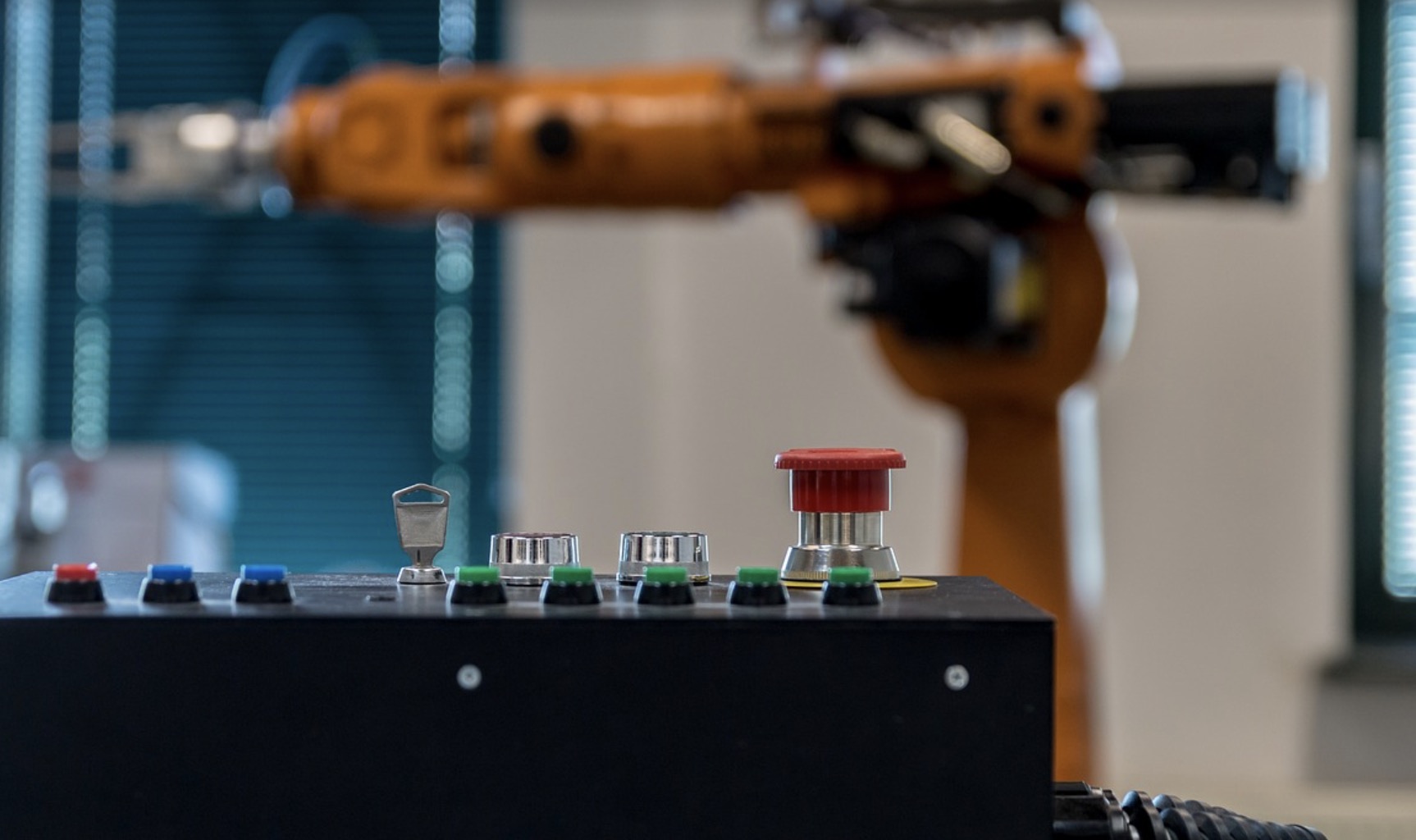

Fundamentally, the job of force sensors and load cells are interrelated. This is due to the fact that force sensors and load cells read and record weight of objects and their range of motion. In the example of a processing plant, there is the need for determining weight and precision mechanical force on processing operations.

In most cases, if the processing operation relies on a robotic application where the product processed requires compression, it is necessary to know the weight of the force on the robotic equipment during the course of the operational function.

How to Measure Motion and Force with Force Sensors and Load Cells

As its name indicates a force sensor measures force on parts and equipment. It can be stand and lever operated or a hand held digital device that measures movement (travel) and weight of force in pounds.A load cell measures force as it is in motion by determining the effect of the weight of force on a body or structure and is then converted into SI units. For instance, industrial plants where hoppers contain liquid or dry materials, this requires measurement using a load cell device as a transducer.

When force is applied, load cells receive an electrical signal that measures the weight of the force and the signal changes the read out in proportion to the signal received.

Conclusion

Contact information

Load Indicator AB

Aröds Industriväg 58

S-422 43 Hisings Backa